Benefits of building from straw

Heat

Straw walls have good thermal properties. Our standard straw panel with an interior clay finish and a ventilated facade or an exterior clay plaster has the thermal transmittance of 0,13 W/m²K. It guarantees low heating costs even in the coldest periods of winter. At the same time, well-insulated straw walls will allow you to feel comfortably cool during hot summer days. The compressed straw layer has a thermal conductivity λD=0,059 W/m2K.

Ecology

Straw is a waste material of agriculture. Using straw as construction material locks CO2 within the built structures. Wood, clay and straw naturally exist in nature and do not need to be produced. For example, the embodied energy of straw is 4 kW/m3, whereas for conventional brick it is 1462 kW/m3. In order to produce building materials like bricks, cement or mineral wool a great amount of energy is needed. It doesn’t come from anywhere and is usually gained from burning fossil fuels, further adding up to the concentration of CO2 in the atmosphere.

Microclimate

A combination of straw, wood and clay creates a perfect range of indoor humidity levels at 40-50% without additional mechanical equipment. Unlike usage of air and wind barriers in conventional construction for keeping insulation dry, straw and clay building techniques allow moisture to move freely within the external structure. Clay plaster used for interior finishes has an ability to absorb excess moisture and to release it back when the humidity level indoors drops down. Clay plaster also works as a thermal buffer reducing fast temperature changes indoors.

Sound insulation

Our straw panels have outstanding sound insulation properties. Being a structural element it can reduce external noise levels up to 57 dB. One more advantage of the straw house - there is no need for additional sound insulation to meet the regular building requirement.

Construction speed

One of the greatest advantages of building with straw panels is construction speed. For example, construction of 120 square meters house walls of straw panels takes only 1 day, the straw panel roof will be done in 1 day as well. Only a small team of 2-3 people is needed for the task. Fast construction saves money and time.

Video of construction

We are constantly looking for partners: architectural firms, construction companies, resellers, associations, local initiatives and researchers to promote and materialize the idea that we deeply believe will transform the building sector in the near future and significantly contribute to saving the planet.

DESIGNED TO ENJOY LIFE, WITH LOVE AND RESPECT FOR NATURE.

TECHNICAL INFORMATION

Only certified dried timber, class C24 is used for producing the timber frames of our straw panels. The standard thickness of the panels is 45 cm. The height and length are variable dimensions and can be adjusted according to the project and transportation requirements. During the production, straw is compressed to the standardised level and all the open straw surfaces are cut to be even by our own developed machinery. We can produce straw panels for walls, roofs and intermediate floors. According to the project, the thickness of the panels can vary from 30 cm to 48 cm.

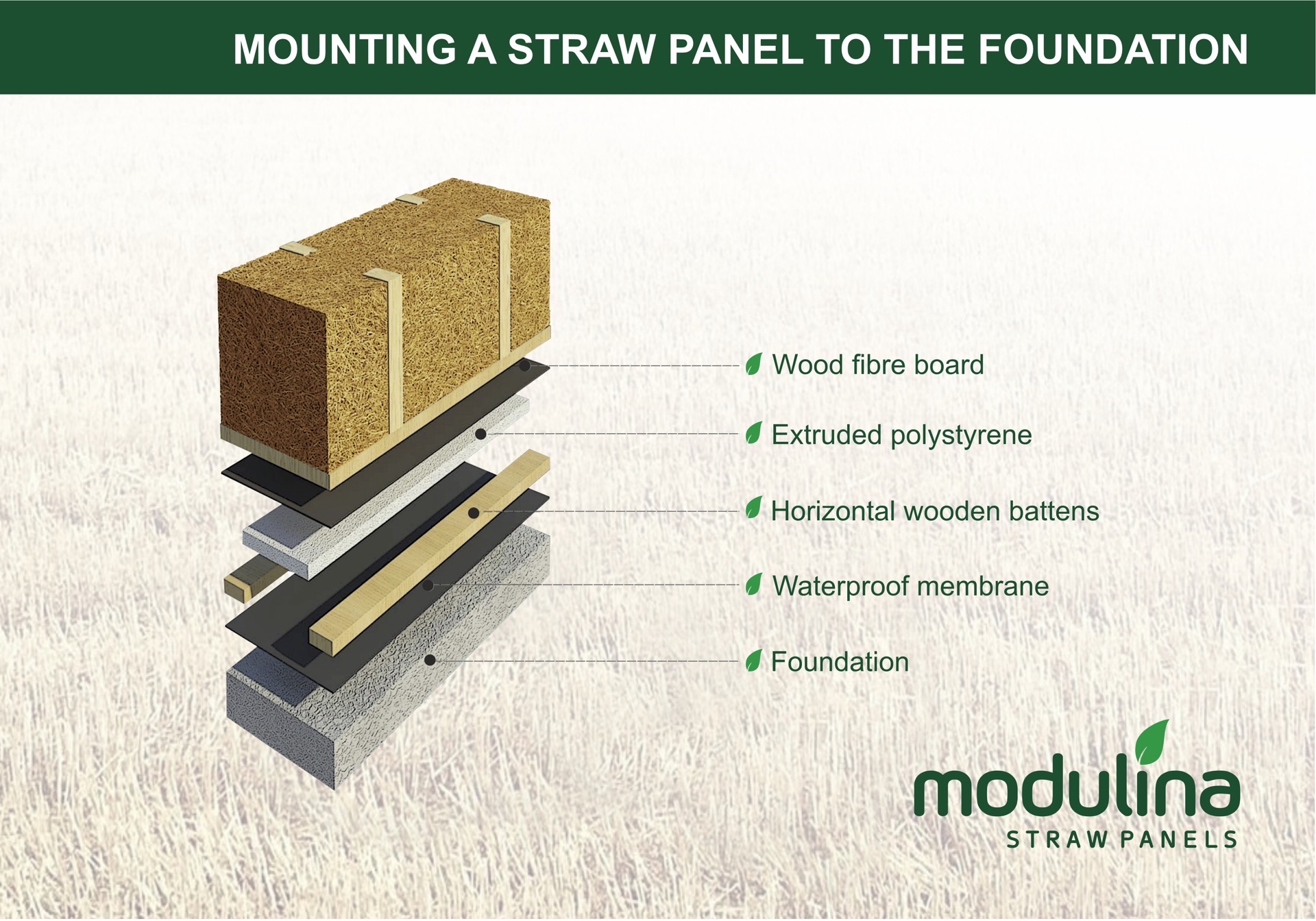

A separate base layer is formed between foundation and a straw panel, which will transfer the loads to the foundation. It consists of two horizontal wooden battens and XPS insulation in between. A slim wood fibre board is attached on top. This base is secured to the foundation with bolts and the straw panel is attached to the horizontal battens via screws.

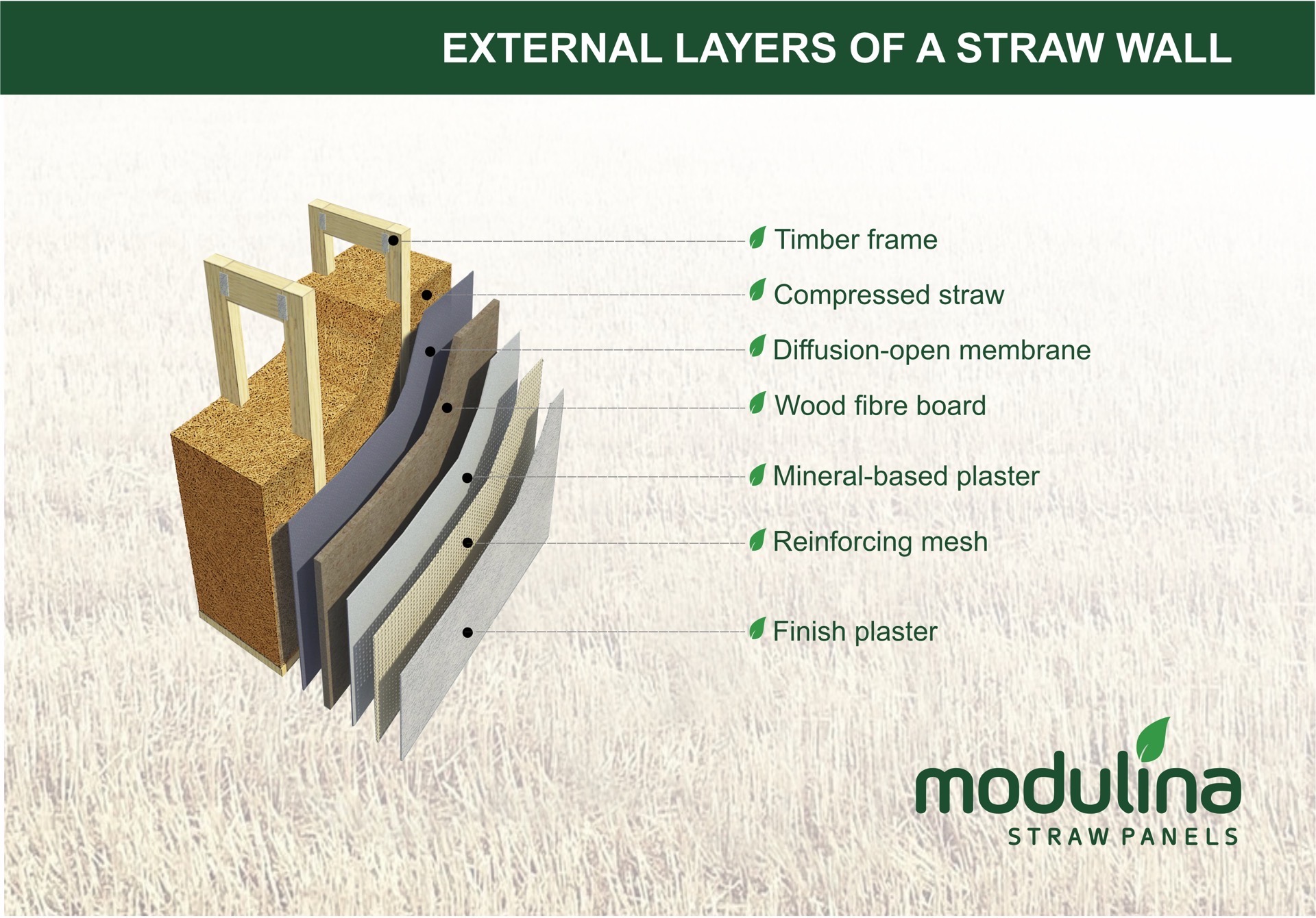

A diffusion-open air membrane is attached to a straw panel. The membrane will protect it from rain during the construction phase and will ensure airtightness of a building. Wood fibre boards are installed afterwards. 24 to 100 mm thick boards can be chosen depending on the desired thermal insulation value. Any kind of ventilated facade is mounted on top. Clay or lime plaster exterior finishes can be applied directly on the wood fibre boards.

A base layer from brown clay is plastered including a mesh for reinforcement. On top of that, a fine white clay plaster mix of 2-3 mm is used as a finish layer. Natural pigments can be added to the mix to get the desired color or it can be later painted with special clay paints. Total clay plaster layer thickness is around 30 mm.

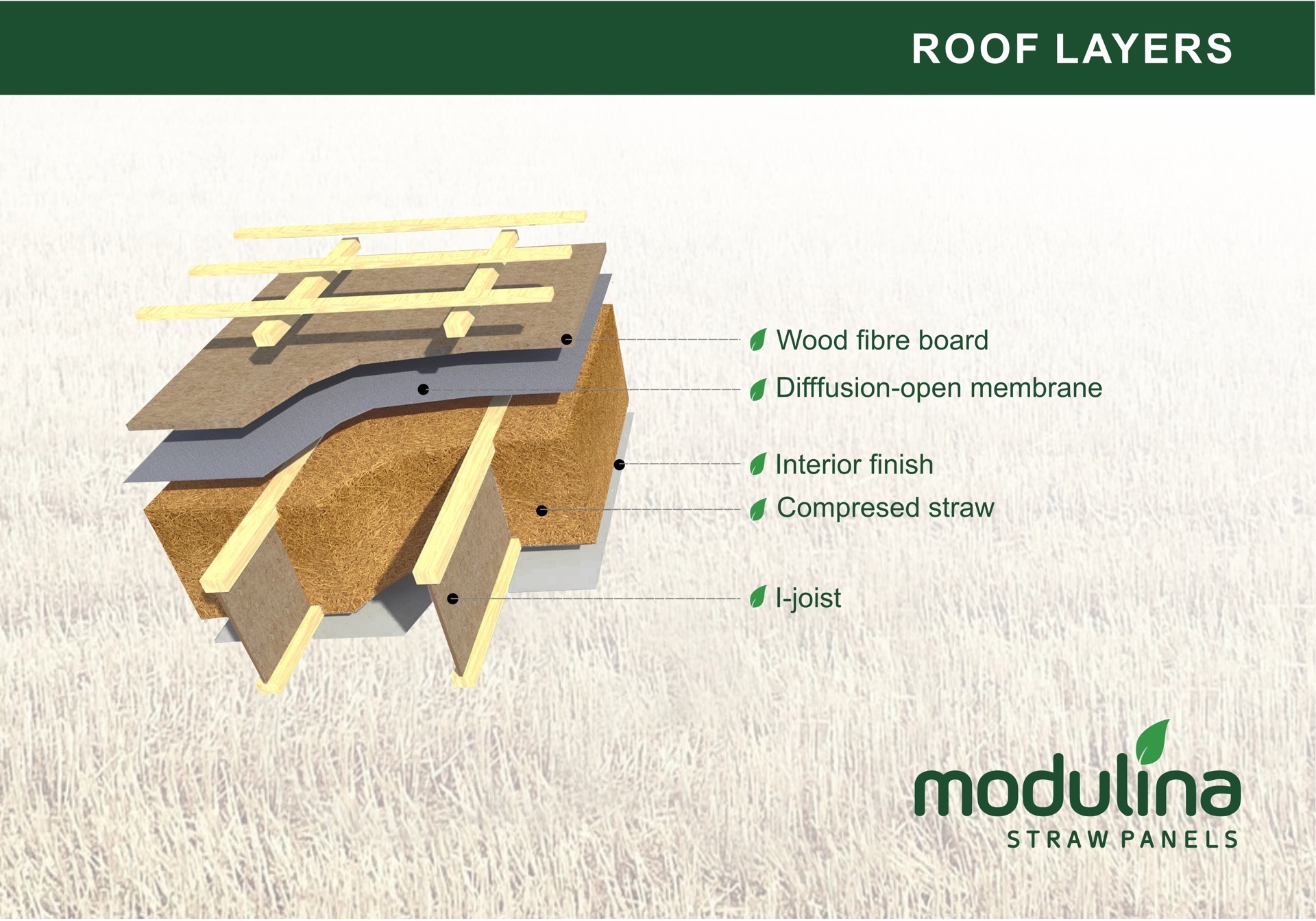

The load-bearing structure for the roof panels is I-beams allowing to cover longer spans. Straw is compressed to the same density as for the walls. A diffusion-open air membrane is attached to the top of the panel. Wood fibre boards are installed afterwards. It adds up additional thermal resistance for the roof and prolongs the lifetime of the membrane below while still letting the moisture to escape being a diffusion-open board itself. Any kind of roofing system is mounted on top.

Prices

To find out how much your home will cost to build out of “Modulina” produced straw panels, you need to multiply the area of the house walls by 1 square meter straw panel price, which currently starts at 90 EUR / m² (without VAT). Do not include doors and windows areas into walls area. Also we can produce straw overlays, which cost EUR 100 / m²(excluding VAT) and the straw roof constructions, which cost EUR 105 / m² (excluding VAT).

Preliminary calculation:

If you want to calculate the price of the walls and do not know the doors’ and windows area, we suggest using the preliminary price calculation methodology, i.e. external walls’ perimeter multiply by height of walls, and the resulting value multiply by one square meter of straw panel price that according to this method starts from 70 EUR / m².

Eg.: 100 m² sized house is quadrangle, one wall length - 10 m, four walls - 10 x 4 = 40 m, wall height is 3 m, 40 m x 3 m = 120 m² wall area, and the preliminary cost of 120 m² x 70 EUR = 8 400 EUR. Prices do not include VAT. 1 m² wall price may vary depending on the complexity of the design and other technical parameters.

Preliminary calculation:

If you want to calculate the price of the walls and do not know the doors’ and windows area, we suggest using the preliminary price calculation methodology, i.e. external walls’ perimeter multiply by height of walls, and the resulting value multiply by one square meter of straw panel price that according to this method starts from 70 EUR / m².

Eg.: 100 m² sized house is quadrangle, one wall length - 10 m, four walls - 10 x 4 = 40 m, wall height is 3 m, 40 m x 3 m = 120 m² wall area, and the preliminary cost of 120 m² x 70 EUR = 8 400 EUR. Prices do not include VAT. 1 m² wall price may vary depending on the complexity of the design and other technical parameters.